article

Wednesday, January 26, 2011

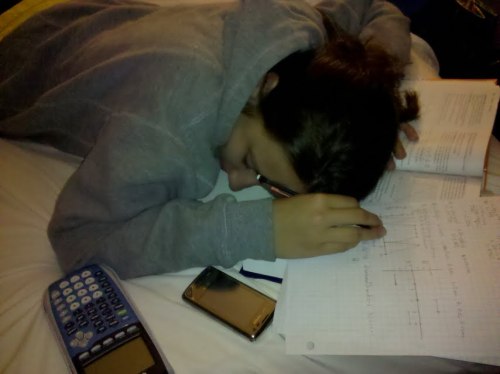

bragging on the oldest

with a part time job, volleyball practice and normal load of homework for the average gifted straight A student, my baby girl has been burning the candle at both ends.i have to say a lump of pride formed in my throat when i seen this, she works hard and will deserve everything she gets out of life

with a part time job, volleyball practice and normal load of homework for the average gifted straight A student, my baby girl has been burning the candle at both ends.

i have to say a lump of pride formed in my throat when i seen this, she works hard and will deserve everything she gets out of life

a little about my oldest daughter sam, she has always been outgoing and friendly as a child and all her school work seemed to come fairly easy for her. i believe she has had 2 B’s in her life on her report card, and they were not subjects that would concern a parent for their child’s future prospects.

straight A’s from k-11 with 2 exceptions, she has taken AP classes last year which on grading scale have more value then honors classes so her grade point average is over 4.0 (4.22 last i heard) ranking wise she is in top 10 (6-7 i believe) in her class.

she has played clarinet, bass clarinet, piano, xylophone, and almost any other instrument the teacher would ask her to try. she was always in a gifted class for advanced learning that was hand picked by a group of teachers, she has been in and placed or won several science fairs, spelling bees, speech competitions etc. etc.

once she got to high school she auditioned for the art school in our town that is academically heads and shoulders above the rest of the district on the state mandated criteria.

she was accepted for piano (1 of only 7 chosen city wide) and a creative writing magnet and has continued to impress and amaze every teacher she has had. going to open houses and parent teacher conferences has always been a pleasure because they have done nothing but praise her for her attitude and abilities. she has won some gold key writing contests for her creative writing class.

the summer between her 7th and 8th grade year she found out about a summer program called “Wright Stepp”. this was a program that introduced girls and minorities to all phases engineering at the local college Wright State University.

the concept is they spend 3 weeks each summer going to the college and taken tours and classes to expose them to all aspects of engineering and it lasts 4 summers. At the end of those 4 summers, if you kept a B average, never missed a day in the summer and didn’t get in any trouble each student would receive a 4 year full scholarship to Wright State, which she finished last year so that was in her pocket as she started the 11th grade.

then she comes home this spring with papers about another program at the same college called “Horizons in Medicine” which is a 5 week summer program where ther spend half the day at college and half the day job shadowing a doctor in the field of their choice, at the end of this each student got 1 full year scholarship.

in this program there would be one student picked by the faculty that they thought showed the most potential or was the most deserving amongst the group of 20 students and they would receive a 3 extra years on top of the 1 year for the program. you guessed it my baby got picked, she has 8 years of full tuition value in her back pocket and she just started her senior year.

she gets upset with me cause i’m always bragging about her whenever the chance come up but really, how could you not, she makes me so proud i could cry (although no one would ever see that happen and i’ll deny it ever did)

i am blessed with all 3 of my children and truly do not deserve the angels i have.

the 3 and 13 year old is just as amazing but thats another whole blog for later.

just rambling

working on a few large programs for work that involve a little “waiting” time so i figured maybe i would ramble on here.

we have been steady swamped at work since the first of the year, hours have been pretty unlimited and with my addictive personality that means i been doing between 60 -70 a week on a regular basis. most weeks working all 7 days, at least half days on weekends.

our customer keeps increasing the orders beyond what we are capable of producing.

in the last 6 months we have bought 6 new mills (4- 5 axis and 2- 3 axis) in my department alone and it is still not enough to keep up.

get in before 7 and leave around 7 everyday which leaves only a few hours at night to interact with the little ones and the wife works part-time around my schedule.

the 17 year old is always at some activity, ie. volleyball, honor society, buried in homework at the computer. the 13 year old is in soccer and the phone and jazz band, so that mostly leave me and the 3 year old to entertain ourselves.

this includes board and video games and “G” movies, lots of trips to the park, bike ride in the neighborhood, walks to the store and the ice cream shop. the one thing i have noticed is having older sisters has really broadened the littlest ones vocabulary, some of the things she says and the words she uses just don’t sound right from a 3 year old.

every conversation is a fun experience and she is only 3 by the time she is 10 i don’t stand a chance at winning an argument.

Jens Pulver

Jens Pulver epitomizes the “hard working everyman” that lives check to check but drives on to support his family. Even in his loss the crowd went crazy for him at WEC47, he jumped up on each side of the cage and the crowd went wild. He is everyone of us that do what we do because we are men and that’s what men do to take care of their responsibilities and be able to hold their head up.

Based on his salary at WEC47, the respect of fans and peers are the bonus that his career has given him, not the riches and fame that some others have gotten.

people like him are what the next generation of humans need to understand and use as examples so hardwork and loyalty don’t fade away in our society.

I hope there is always a place somewhere in this sport for the people like Jens, we owe them that much.

this was a post i wrote for sunday junkie after watching WEC live in Columbus.

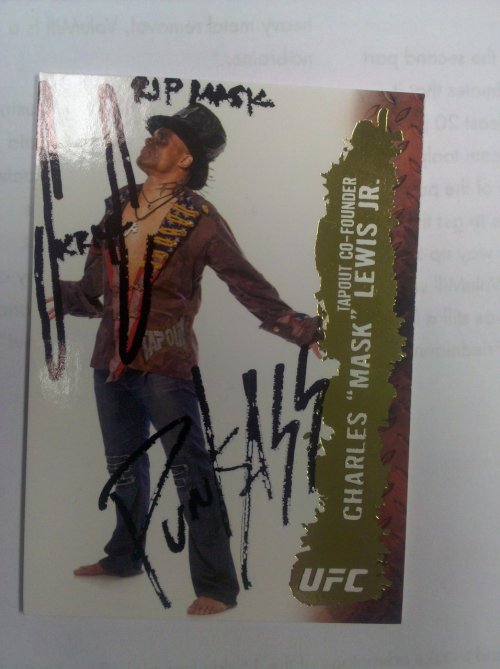

MASK

MASK

I was thinking of the impact Mask had on the quality of fighter I watch today. I was a fan of the Tapout show from episode one, even when everyone I knew thought it was a joke because of the makeup but I told them great young fighters were being scouted on the show and a lot of those are up and coming fighters I watch today.

Johnny Hendricks, jake Rosholt, Donald Cerroene, Leonard Garcia, Damacio Page, Antonio Banuelos, Matt Major, are just some of the talent they scouted that have made a serious impact on the sport and some may have never even be known of, if it wasn’t for the effort that charles made to grow the sport and support the talent that was needed for that growth.

His impact will be felt for many many years to come just from the short time we had him because of his passion for the sport. The Tapout brand has become as synonymous with MMA as the UFC brand has, that itself speaks volumes about the support and growth that his dream has provided the sport.

there are many great people in this sport, that exemplify the heart, courage and dedication of a true warrior and Charles “mask’ Lewis was no doubt one of them. his place in the UFC Hall of Fame is well deserving and his mark on this sport has been made. Tapout will be bigger then Nike just watch, the recent deal is the next step in that process. Mask is smiling

work

my job

just a little about what i do to fill in some blanks.

i work in a machine shop, i’m now the supervisor of the CNC mill department.

i schedule the jobs for the 19 machines in my department, decide what machine and what operator will make the parts required.

for the most part i program all the machines myself and design the processes that we will use to manufacture them.

i am in the process of training a couple guys to help pick up slack with programming but this takes a while to master, not the programming side of it as much as the process side.

how you will go about making the part from start to finish, what tools, what order features need to be done, how to locate and hold the part to do them, all that knowledge comes from trail and error so i still have to stay involved in that part.

i try to let them make mistakes to learn from and try to help them avoid the big ones, that i already paid the dues on.

the software i use to program the machine to make the parts is Edgecam. (http://www.edgecam.com/) it’s a CAM software (computer aided manufacturing)

it basically makes code for the machine to know what to do and where to do it. once you set up the machine with the proper locations and tools it needs the machine takes over and machines the part in the order and with the tools you told it to in the code.

75% of the parts we make are made of stainless steel the rest is comprised of any other material, we cut anything. from really hard and tough, high nickel content material to aluminum or plastics. every material is machinable once you figure out what tools you need and how to use them.

i started at at this shop in 1992 and was brought in to be the lead set up guy for the person that did my current job at the time. (he is still my boss we just both shifted up a notch.)

we manufacture many different parts for many different industries including:

medical parts - mostly tools used during operations

aerospace part - variety of prototype parts for research and development.

automotive parts - prototype brackets and valves, some short run production

printing press parts - parts for high speed printing presses made by kodak.

being as diversified as we are helps us to maintain a steady workload, some industry is always up when another is down, so we tend to ride the wave.

the only problem becomes when more then one is up at the same time, then we end up overloaded like we have been all this year.

this year we have added 6 new machines in my department and 4 more in the other departments. we have also hired 8-10 people so far, we are close to 1/3 growth in capacity before the year is over in my deparment.

4 of my 6 new machines are 5 axis trunnion machines (http://www.hurco.com/USA/Products/Machining_Centers/5-Axis/Useries/Pages/U_Series.aspx)

we already had 2 Haas trunion machines that we purchased in 2005, so i was familiar with the concept of 5 axis machining.

this is basically holding a piece of material and twisting and spinning it around to different angles so my cutting tools can access every side of the part i’m making except the side i’m holding on to.

this makes almost every part a 2 step process, 1 in the trunnion doing 5 sides of the part and the second finishing the side we held onto for the first operation, thus eliminating multiple set ups that the parts used to require when you could only access one side at a time.

the challenge of deciding how to go about this whole process, what tools to use, how to hold it, what order to do each feature so it does’t affect another. etc. and figuring out how to do it right the first time out of the gate is the fun part of my job.

being the guy that has to be the babysitter and tell grown men that are being paid to earn their money by staying busy, and dealing with all the problems immature people create is the suckass part of my job that i hate.

as busy as we have been I’ve got unlimited amount of hours available for the taking and have worked 7 days a week at around 65 hours a week for this whole year so far. i took off maybe 6 days total and 3 were for WEC/Arnold’s in Columbus last March. I’m not sure whether it’s a sense of responsibility or just plain greed that makes it so hard to say no when the hours are there. i do go in early and try not to stay late very often so i get time for the young ones. only half day on weekends while the kids sleep thru morning then off to plans with them.

thats the nutshell version i guess, hit me up if you got questions

article in local paper

Article in local paper about a project we work on with local high school kids

http://www.daytondailynews.com/news/community/kettering/fairmont-students-learn-robot-skills-955144.html

Fairmont students learn robot skills

By Adele Koehnen, Contributing Writer

3:29 PM Thursday, September 30, 2010

Three men at Triangle Precision Industries located in the Delco Business Park have taken mentoring a step further by helping Fairmont High School seniors design and execute a robot for competition next month.

“Under David Lord, project teacher of Lead The Way at Fairmont, six seniors and one junior come three days a week to our shop to study last year’s robot and work on a design of their own,” said Tim Friedman, a computer numerical control supervisor at Triangle.

The students learned that a design must be manufacturable and not give off any debris or metal parts that may cause injury. The expertise of Lee Danner, a lathe operator, and Brian Thompson, a welder at Triangle, helps the students in the making of the robot.

Competition among other high schools in the Greater Miami Valley is what generates the incentive and enthusiasm to design and build the best robot they can, said Lord, a Fairmont teacher for 15 years.

“This group will be replaced with another group of seniors for the spring competition. A junior is included in the group for learning what’s going on for the next year. After the robot project the seniors work on an original project of their own,” Lord said.

Triangle Precision Industries is a member of the Dayton Tooling Manufacturing Association, which has a four-year apprentice program that includes on-job training and related classroom time. Friedman is a graduate of the Greene County Vocational School and has worked at Triangle Industries since 1992.

The Association will hold its annual show Oct. 20-21 at the Dayton Airport Expo Center. The public is invited to see the latest in technologies, trends, products and solutions. And the high school students and their robots get to fight it out with their custom-built remote-controlled robots.

“It’s called BOTS, and it’s an event not to be missed,” Friedman said.

The show is free and the hours are 10 a.m. to 8 p.m. Oct. 20, and 9 a.m. to 6 p.m. Oct. 21. For more, call Friedman at (937) 299-6776, ext.116.

Contact this columnist at (937) 433-1552 or adeleauk4737@sbcglobal.net.

this is about a project my shop works with the local high school on building a robot to fight in competition twice a year.

really cool stuff, we have as much fun as the kids do.

Subscribe to:

Posts (Atom)